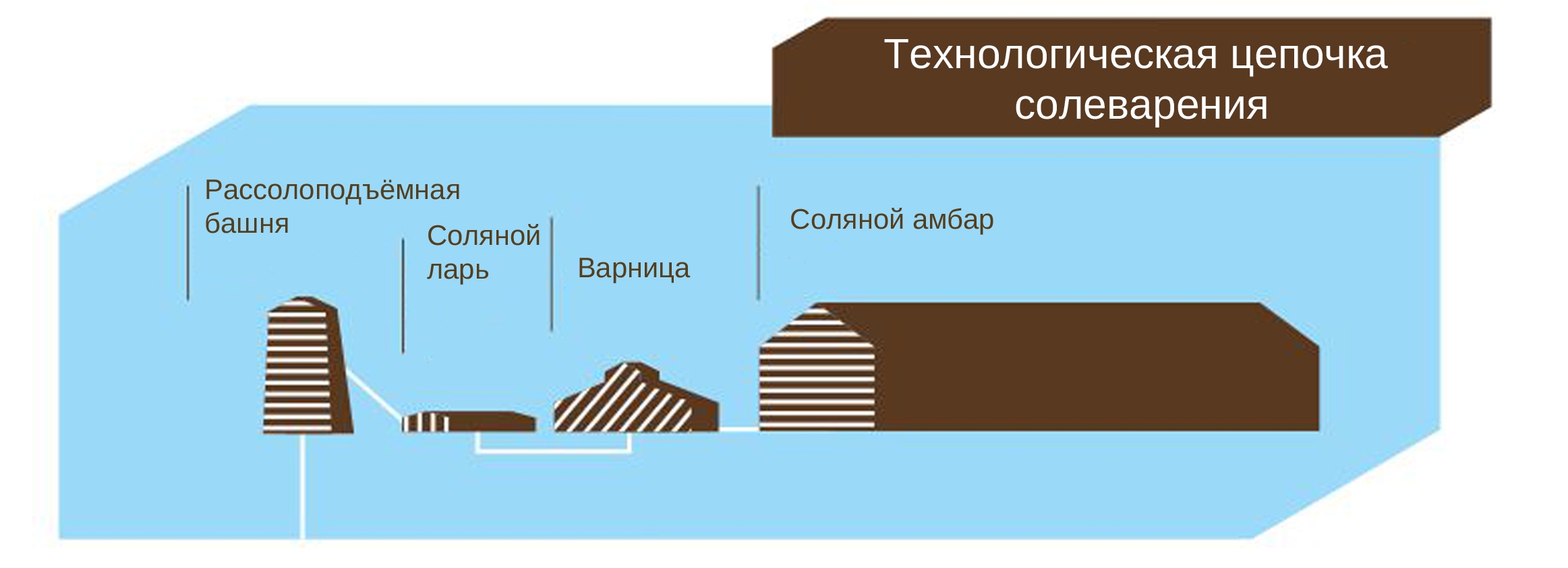

A full complex of salt-works included salt lifting wells and towers, salt chests, salteries and salt barns.

Brine had to be pumped out of the ground. Before 1870 drilling wells to lift salt had been made by hand: a wooden pine frame was sunk into the well, and then a drilling bit, chosen according to the nature of the soil, was lifted with the help of a windlass and quickly lowered. As the frame sunk, the bit was rotated at an angle and the brine was lifted with special bailers by a pipe made of pine log with a diameter of two inches” – 62 cm. Caulked pipes were placed into the well and flowing brine was directed either onto chrens or into reservoirs. Drilling could take from 3 to 5 years, and salt lifting pipe became the most expensive element of salt production.

Since the 17th century people started using pumps – a salt lifting tower appeared above the well. Some researchers consider that it was a prototype of a fortress tower. The brine was pumped up to the third level of the tower. A 12-meter tower was firmly grounded. Its blockhouse was wide at the bottom and narrow at the top: the upper logs were thinner, and the length of them became less with the height of the wall. There are no similar constructions above salt wells in Russia.

The flowing brine was directed into the salt chest – the next element of the technological chain of salt evaporation. Salt chests appeared in Prikamye in the last quarter of the 18th century. To strengthen the walls of a chest and protect them from the weight of the brine, vertical logs were put in pairs. The slots between them were carefully filled with resin. All this construction was pushed tightly together with a “hoop” – a horizontal wooden frame. The chest was covered up with a gable roof. Chests were connected with salteries by underground wooden pipes in which the brine was directed into chrens through the holes at the bottom of a chest.

The most important element of the whole cycle was the evaporation of salt. Saltery was the main construction at the salt-works. Traditional salteries were dark-fired, i.e., the firewood was burnt in a four-sided pit-stove with a chren hanging above it, with hipped roof and vapor hole. They were formed in the 18th century and remained practically unchanged. Only in 1895 brick chimneys, so-called “bavarian” salteries, were added to all of them.

Salt was evaporated on chrens (a kind of a tray). They had a size from 125 to 144 square meters and were made of iron sheets 12 mm thick, which were fasten together with iron rivets. A blacksmith making chrens was a very important person at the factory. Only in 1940, welded chrens replaced riveted ones.

Brine was poured on chrens directly during evaporation. It was made while keeping quiet even heat in furnaces. As a result, a slow boiling brine formed crystallized salt. It was collected with special scrapers in the corners of chrens, and then salt was placed on wooden decks (polati) with wooden shovels. There salt was dried. The evaporation of one batch of salt lasted continuously for about a day. 20-25 batches were produced in a row, and then chrens were cleaned and re-loaded with brine again.

Special workers (salt-carriers) collected salt in bags and delivered it to barns, so-called “salt shops”, in which one-year supply of salt was kept for its onward shipment by waterway. The barn was divided into 10 sections – bins where salt was loaded top-down. Barns were located at the water on ‘’ryazhi’’ – log cells. They served not only the foundation for the barn, but also kept salt dry during floods. Barns were huge constructions for that time (length – 52 m, width – 19 m, height up to the roof ridge – 15 m). At first people loaded and unloaded barns manually. Salt-carriers with bags on their backs brought salt to unloading platforms on the roof of the barn. Later there were built rail salt tracks for unloading salt directly into barges, which came close to the barn in spring.

Salt was transported to the markets of Nizhny Novgorod and Rybinsk along the Volga and Kama by vessels-barges of factory owners and merchants selling salt. Special flat-bottomed vessels, which carried from 30 to 65 thousand pounds of salt, were used for it. As a rule, there were some barges united in a salt caravan.

The site was developed by the charity program "Museum Guide"

The site was developed by the charity program "Museum Guide"